Mon-Fri 09:00 - 19:00

aarav@phoenixceramics.com

+91 96622 81857

Mon-Fri 09:00 - 19:00

Mon-Fri 09:00 - 19:00 aarav@phoenixceramics.com

aarav@phoenixceramics.com +91 96622 81857

+91 96622 81857

The CIM process combines the design flexibility of plastic injection molding with the strength and integrity of ceramics to offer cost effective solutions for highly complex part geometries. The CIM process is typically explained as four unique processing steps (Compounding, Molding, Debinding and Sintering) to produce a final part that may or may not need final finishing operations.

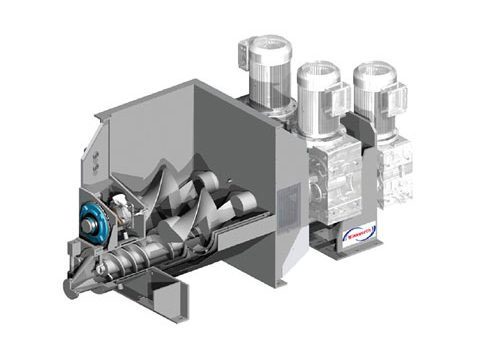

The first step in the CIM manufacturing process is the production of the feedstock that will be used. It begins with characterization of very fine elemental or pre alloyed metal powders (usually less that 20µm). To achieve the flow characteristics that are required in the injection molding process the powder is mixed with thermoplastic polymers (known as binders) in order to for a mixture in which every metal particle is uniformly coated with the binder. Typically, binders comprise of 40% by volume of the feedstock. Once cooled, this mixture is then granulated into pellets to form feedstock for the injection molding machines.

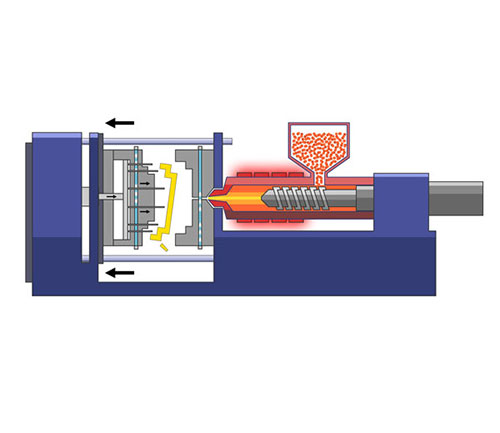

The next step is the molding of the part in a conventional injection molding machine. The feedstock pellets are gravity fed from a hopper into the machine barrel where the heaters melt the binders, bringing the feedstock to the consistency of toothpaste. A reciprocating screw forces the material into the two part mold through opening called gates. Once cooled, the part is ejected from the mold with its highly complex geometries formed.

The elected as molded part, known as the green part is composed of ceramic powders and polymer binder from the feedstock.

The ejected as-molded part, known as a “green part,” is still composed of the same proportion of ceramic powder and polymer binder that made up the feedstock, and is approximately 20% larger in all its dimensions than the finished part will be. The next step is to remove most of the binder, leaving behind only enough to serve as a backbone holding the size and geometry of the part completely intact. This process, commonly referred to as “debinding,” is performed by solvent (solvent debinding) & thermally, which in case involves a solvent bath as the initial step. After debinding, the part is referred to as a “brown part.”

In this process, which is performed in the highly controlled atmosphere or natural atmosphere batch furnace, the brown part is staged on a ceramic setter and is then subjected to a precisely monitored temperature profile that gradually increases to ceramics melting temperature. The remaining binder is removed in the early part of this cycle, followed by the elimination of pores and the fusing of the ceramic particles as the part shrinks isotopically to its design dimensions and transforms into a dense solid. The sintered density is usually 100% of theoretical. The end result is a net-shape or near-net-shape ceramic component. Of course, if necessary, post-sintering operations such as grinding, machining, coating, and others, may be performed on the part to achieve tighter tolerances or enhanced properties.